Description

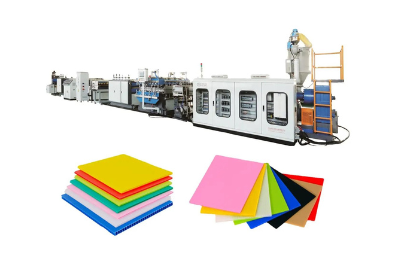

Plastic PP hollow corrugated board making machine for packing box for fruit and vegetables,toy,fragile items,gift box,tarays

Why choose our machine?

1,Smart automatic easy to operate PP hollow corrugated board machine

Intelligent, automatic and easy to operate-the Gereration PP plastic hollow board and corrugated board extrusion machine launched by us is very popular in the market.

Through online guidance, we have remotely assisted many new customers to successfully complete the installation and operation of the machine in a short time, and produce qualified PP hollow corrugated board.This is even more commendable in the face of difficult global travel.

2,High capacity 0-80% Filler (Calcium) PP hollow corrugated board making machine

Intelligent, automatic and easy to operate-the Gereration PP plastic hollow board and corrugated board extrusion machine launched by us is very popular in the market.

Through online guidance, we have remotely assisted many new customers to successfully complete the installation and operation of the machine in a short time, and produce qualified PP hollow corrugated board.This is even more commendable in the face of difficult global travel.

2,High capacity 0-80% Filler (Calcium) PP hollow corrugated board making machine

By using Tongsan PP PE Hollow Profile Sheet Corrugated Sheet Extrusion Machine,it greatly save your material cost and production cost.

Our factory have all series H-Line and S-Line high quality PP hollow corrugated sheet machine ,the width of the products is

1220-3000 mm, and the thickness is 1 mm-12 mm.The extrusion line can reach 2-10 m/min, the high capacity at 200-600 kg/h. We continues to innovate with the industry’s leading level.Looking forward to working with you for a win-win cooperation.

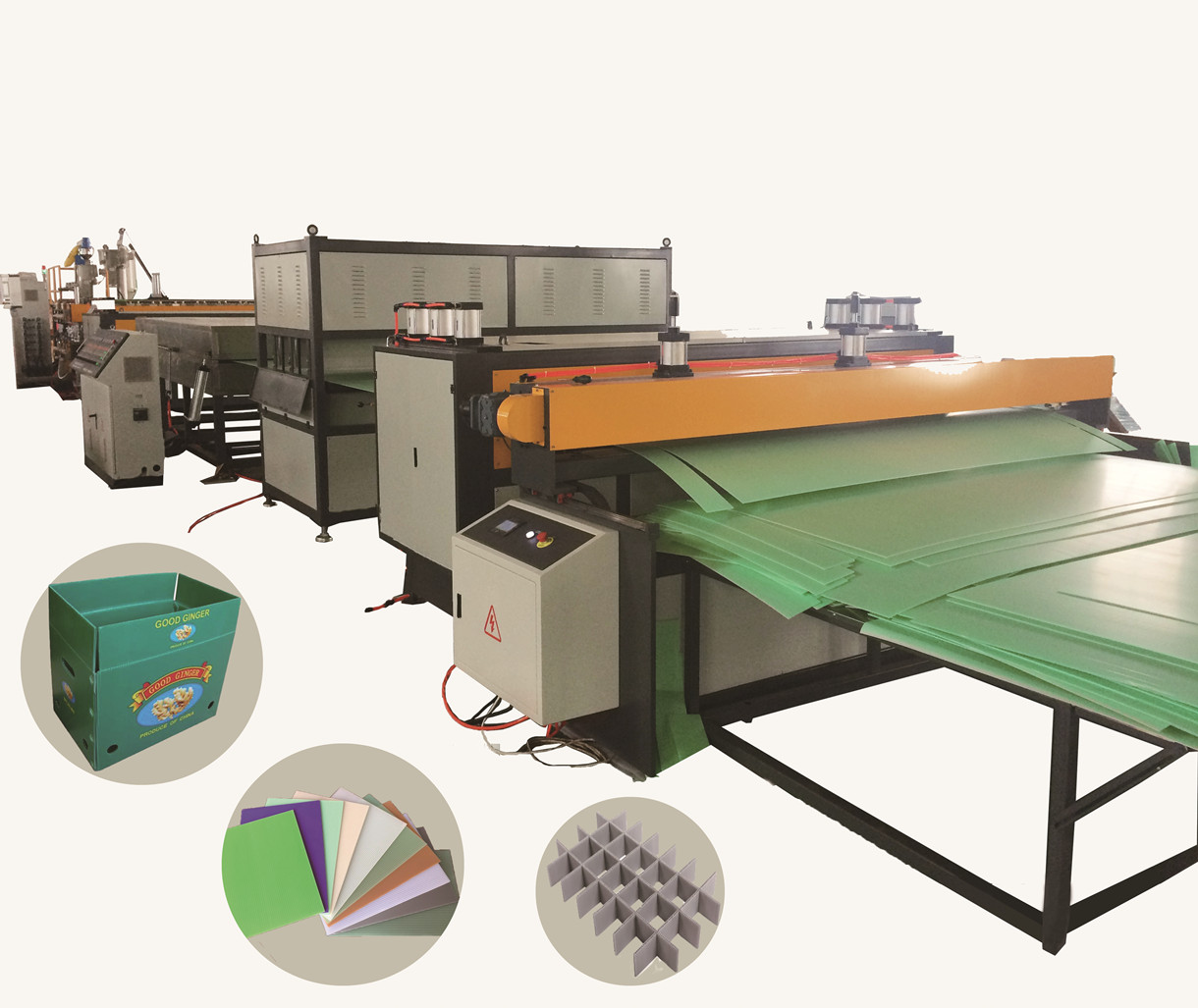

3,Turnkey project for plastic package box making machine

We provide high out production line with professional technology support,and auxiliary machine for package box making

machines,such as printing machine,automatic die cutting machine,package plastic box making machine,welding machine and edge sealing machine.

4,All series PP PE Hollow corrugsted board machine model

1220-3000 mm, and the thickness is 1 mm-12 mm.The extrusion line can reach 2-10 m/min, the high capacity at 200-600 kg/h. We continues to innovate with the industry’s leading level.Looking forward to working with you for a win-win cooperation.

3,Turnkey project for plastic package box making machine

We provide high out production line with professional technology support,and auxiliary machine for package box making

machines,such as printing machine,automatic die cutting machine,package plastic box making machine,welding machine and edge sealing machine.

4,All series PP PE Hollow corrugsted board machine model

Main Technique Parameter | ||||||

Model | TSGZB-1400 | TSGZB-1860 | TSGZB-2300 | TSGZB-2600 | TSGZB-2600 (Co-extrusion) | TSGZB-3000 |

Width | 1220mm | 1700mm | 2100mm | 2450mm | 2450mm | 2800mm |

Thickness | 2-6/5-10mm | 2-6/5-10mm | 2-6/5-10mm | 2-6/5-10mm | 2-6/5-10mm | 2-6/5-10mm |

Extruder Model | SJ-90/36 SJ-100/36 | SJ-100/36 SJ-120/36 | SJ-120/36 | SJ-120/36 | SJ-120/36 SJ-80/36 | SJ-150/36 |

Extruder Capacity | 170-190kg/h | 190-250kg/h | 260-300kg/h | 300-350kg/h | 340-420kg/h | 500-600kg/h |

Main Motor | 55KW | 55-75KW | 75-90KW | 90-110KW | 110+37KW | 132-260kw |

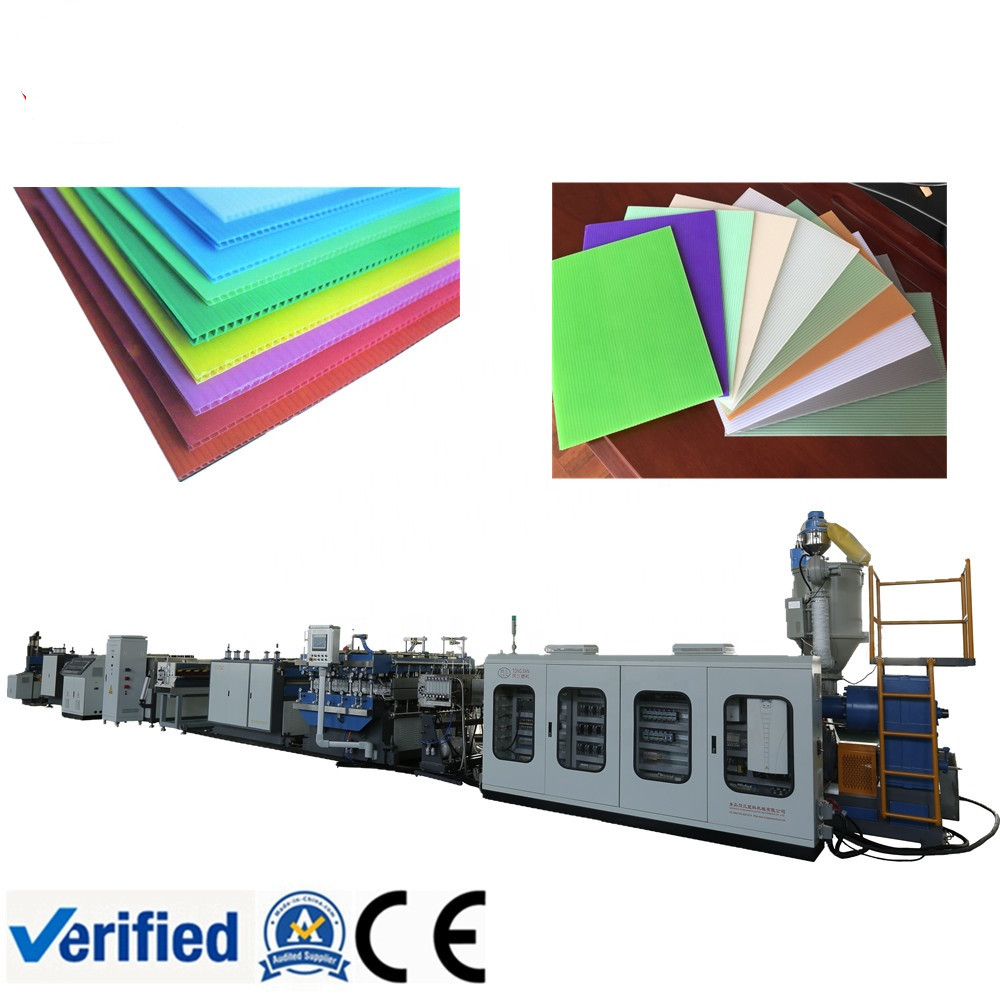

Advantage of PP hollow corrugated board

The plastic hollow sheet is eco-friendly new material in the market.it has the advantage of non-toxic, no smell, pollution-free, water-proof, anti-moisture, corrosion resistance, light weight, tough-resisting, thermal shock proof, economy and durability, rich colors etc, It also has the properties of flexural resistance, tensile resistance and high strength etc.

The plastic hollow sheet is widely used in advertisement, interrior decoration, transportation and package for machinery,

electron, home appliance, medicine, food, glass, agricultural products.

The plastic hollow sheet is widely used in advertisement, interrior decoration, transportation and package for machinery,

electron, home appliance, medicine, food, glass, agricultural products.

Why use PP corrugated box to replace canton box

The PP hollow board is reusable and 100% recyclable, and there is non-pollution in production, it is environment-friendly products which is widely proposed. The paper industry causes environment pollution and the production cost is going up higher and higher. With the vigorous development of e-commerce, the market demands of packing box is bigger and bigger, the future logistics packaging requires light weight、economic and environment-friendly packing material, the plastic hollow sheet completely conforms to this concept, so the plastic hollow sheet has a broad development prospect.

Reviews

There are no reviews yet.