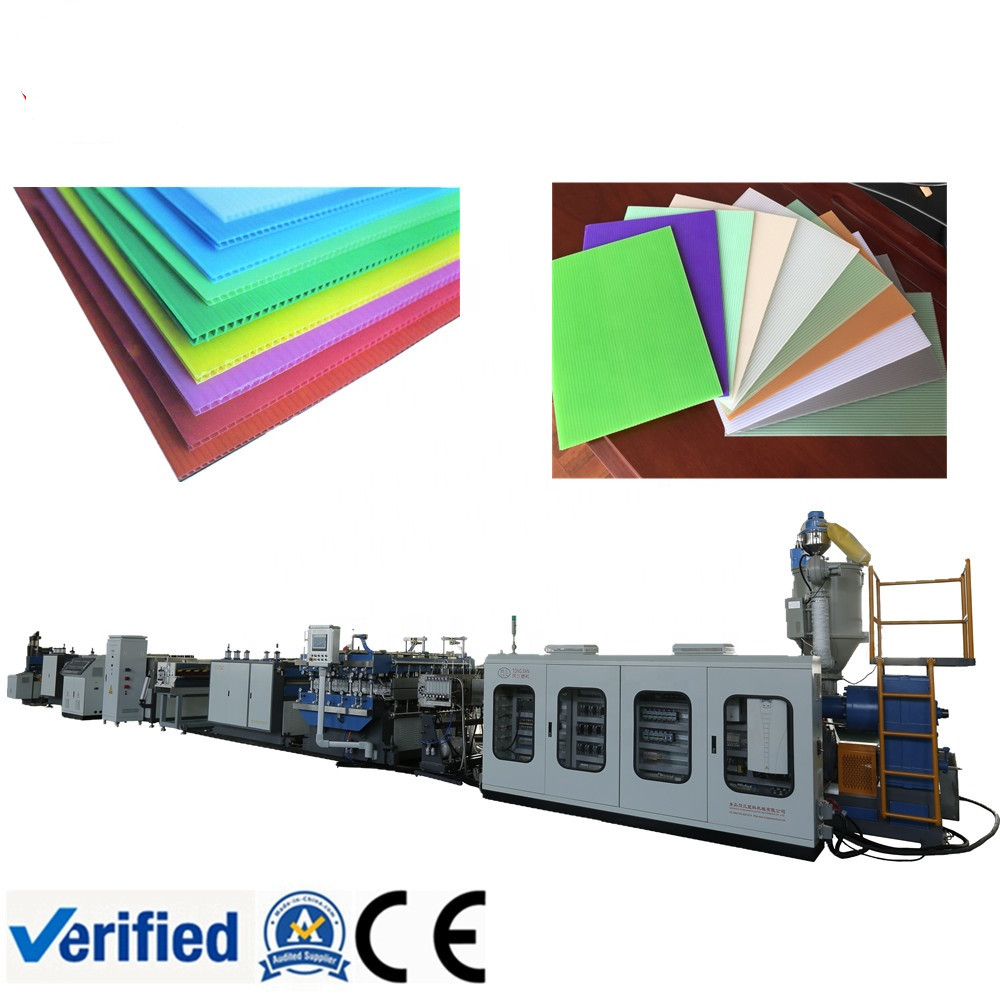

PP hollow sheet machine

pp hollow sheet/board is a new environmentally friendly materials, and gradually replace paper products. pp hollow sheet/board has high transparency, non-toxic, light weight, impact resistance, flame retardant, anti-aging, anti-static, anti-static and other characteristics. pp hollow sheet/board is widely used in precision plastic parts, precision hardware stamping, auto parts, medicine, agriculture, advertising, aerospace and other high-tech fields. The above characteristics of the pp hollow board is the paper products can not reach.

The service life of the pp hollow sheet/board is generally more than 50 times, if the same specification of the packaging box, the price of paper products is 5.00 a calculation, the general use of four times to calculate the average cost of a use is 1.25 a time. And the same pp hollow sheet/board products price is 20, if the pp hollow board use times is 25 times to calculate, the average cost of a use is 0.80/time. With paper products to save 36%, such as the number of times used in 40, then the average cost of one use is 0.5 a time, than paper products to save 60% of the cost, such as the use of 50 times, this cost is obvious.

PP hollow sheet is a kind of packing material that high strength and durable,but light weight. It can be recycled and reused repeatedly, and no pollution to environment. It can be made into box, bin, divider, and other customized shapes, which is used widely in electronic, construction, advertisement,vehicle, medicine, furniture, and home store industries

PP hollow corrugated sheet making machine,the sheet thickness can be 1.6mm-18mm,the width of the sheet can be customized according to customer requirements 915-1220mm.The surface of its products is smooth and clean, the size error is small, can nail, can gouge, corrosion resistance, flame retardant strong and many other advantages. PP hollow building template production line is composed of single screw extruder, hydraulic screen changer, mold, setting machine, primary tractor, annealing furnace, cooling box, secondary tractor, crosscutting machine and conveyor.

Flow chart:

Auto feeder–extruder– mesh change→ mould→ forming→ haul-off→ preheating→ cooling forming→haul-off→ cutting→ stacker

If you are interested in PP hollow sheet machine,pkease contact me at any time.

Mobile/WhatsAPP:+86-15269260792

Email: [email protected]