Description

Wood Plastic WPC machine is developed for using recycled PP/PE plastic mixing with agriculture wastage(such as wood sawdust, rice husk, rice straw, wheat straw) to make eco-friendly construction products, the max. wood percentage can be 70%.

Combining advanced Canadian technology and the domestic practical situation, our company developed the SJMS series WPC machine.

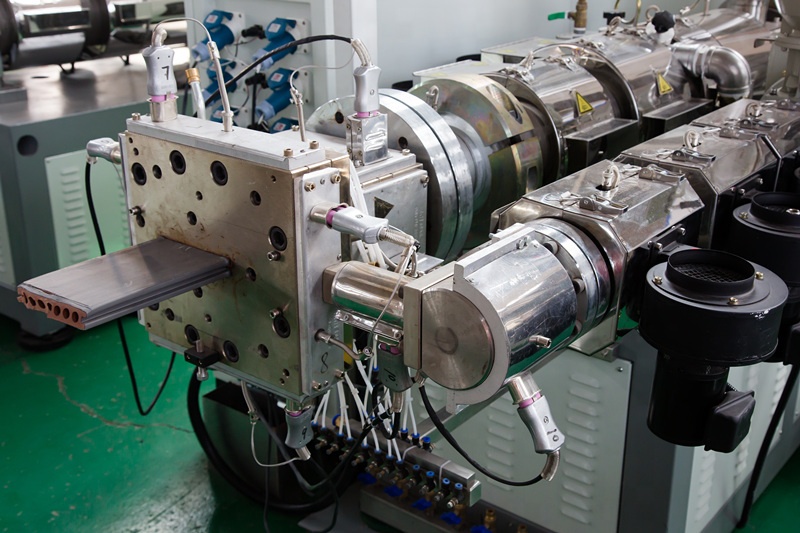

WPC profile extrusion machine is adopted specially designed screw,barrel,mould and unique WPC craft and formula initiated by our company. The extruder can match with the auxiliary machines and moulds perfectly.

The whole production line is of automatic control from the loading to the final discharging. The machines can also be manually adjusted separately. With the advantages of good plastication, low energy-consumption, high output, excellent performance, long endurance,ect.

It can be equipped with relative auxiliary equipment, such as vacuum calibration platform, haul-off machine,cutting machine and material stacker.

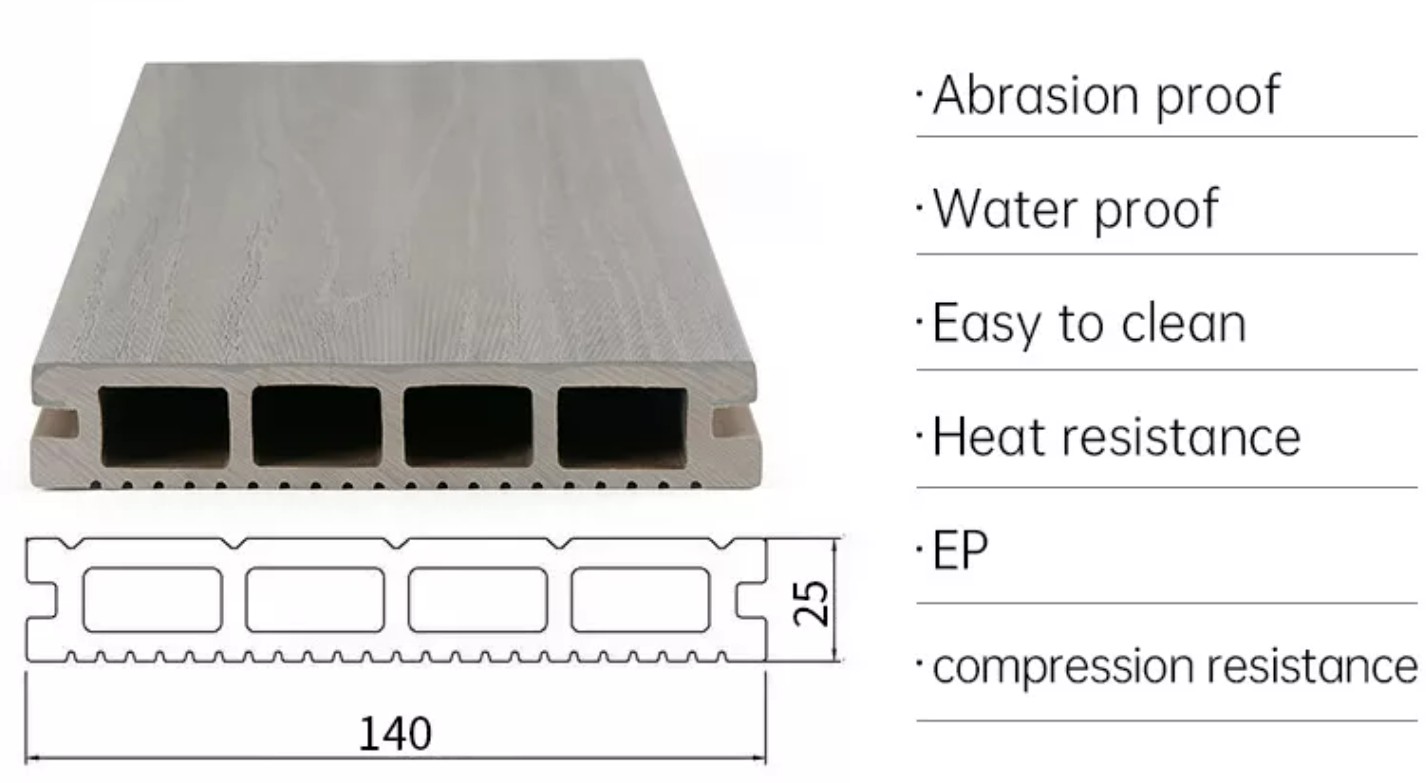

It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets, ect.

materials: wood/rice husk/wheat straw,etc + plastic(can use recyled materials,PP,PE or PVC

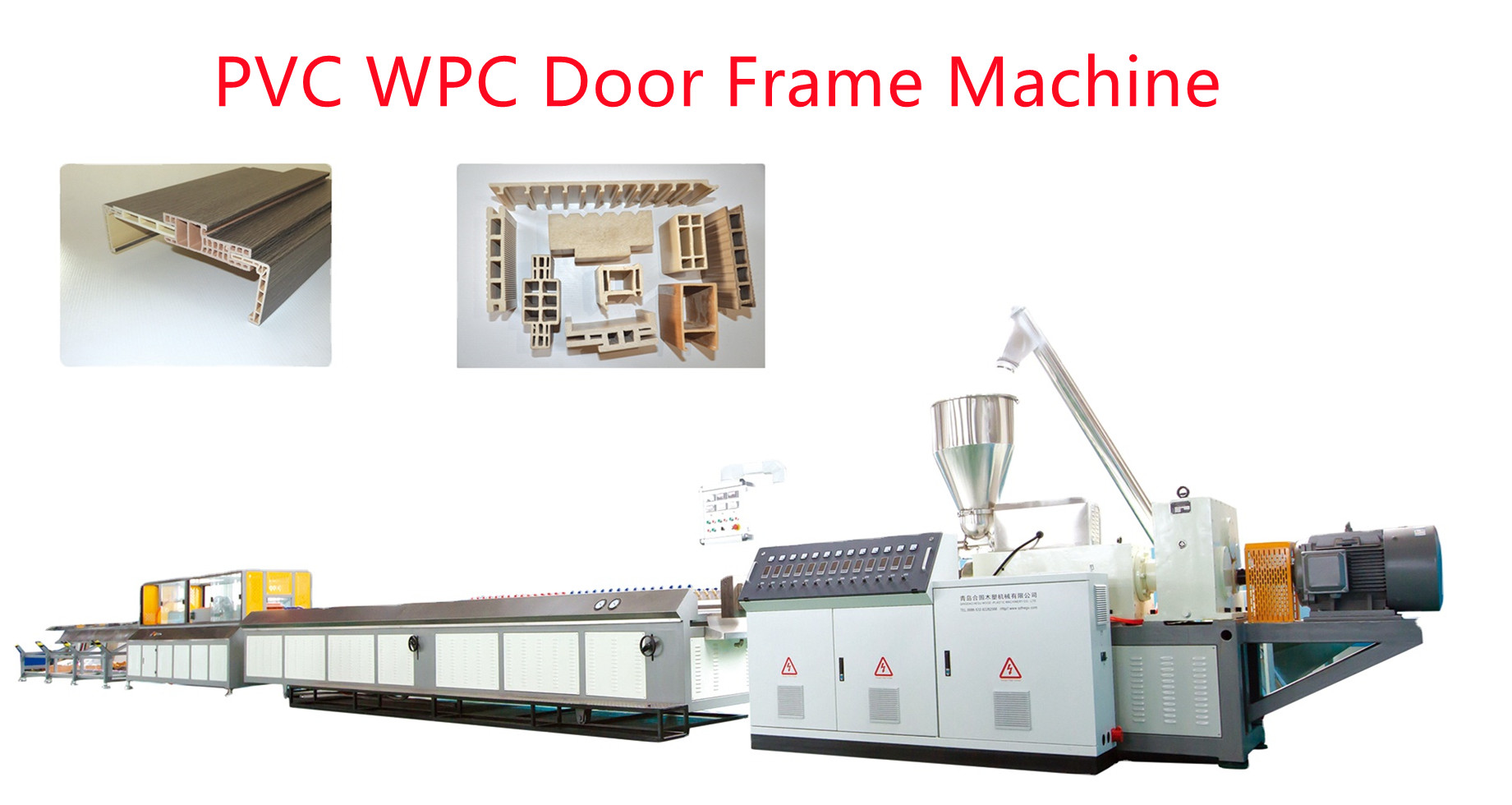

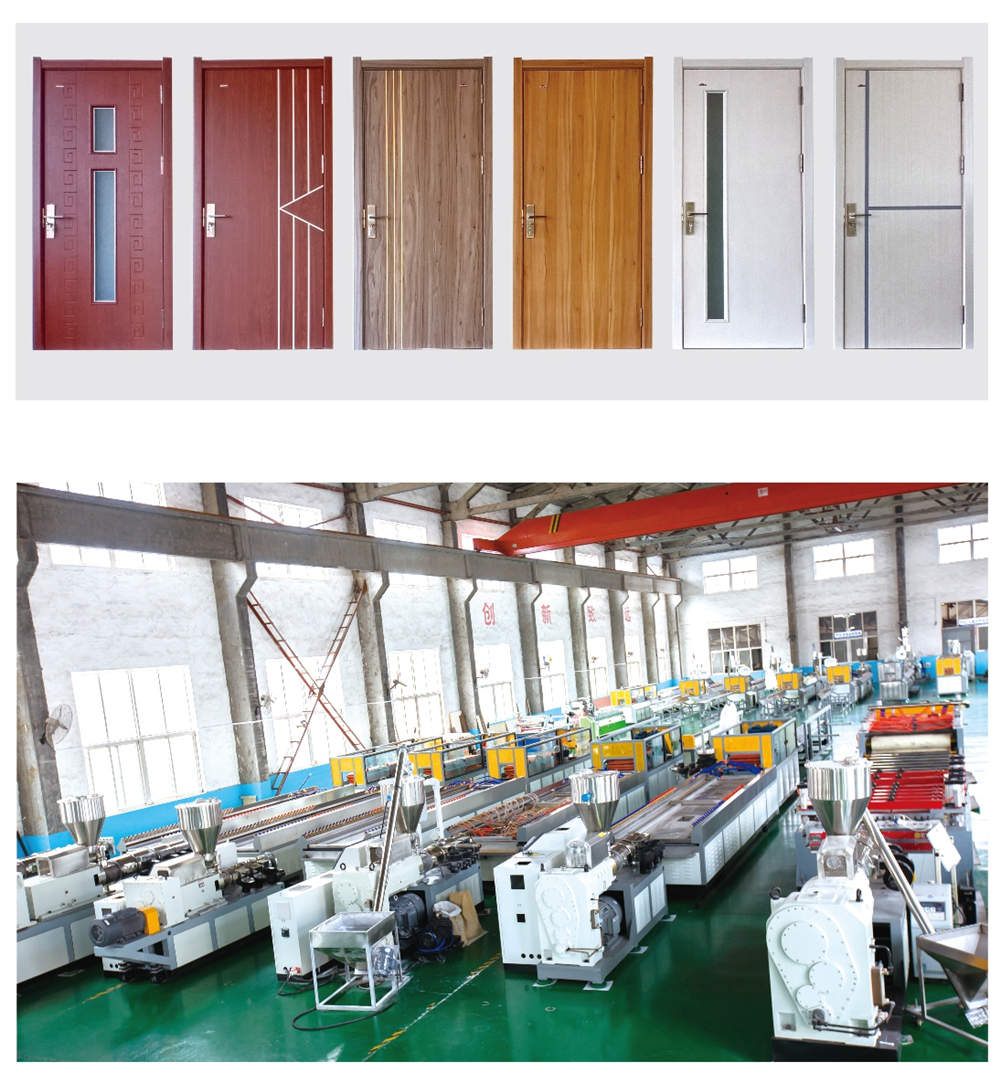

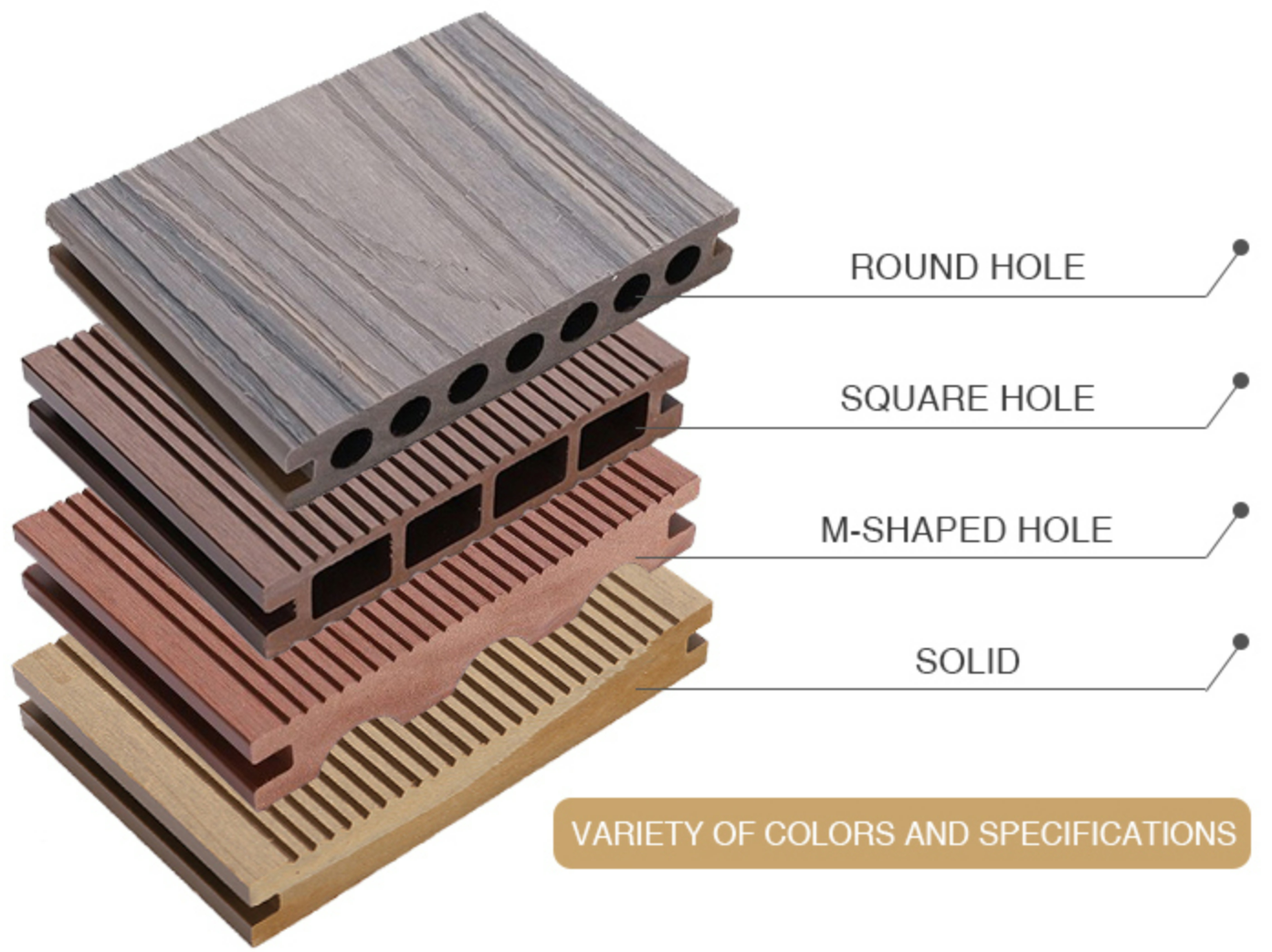

Application: decking profiles,like outdoor and indoor flooring, garden furniture,wall cladding,roof panel,pavillion ,fencing,rail,window frame , door frame,etcMaterial: Wood powder ( waste wood brick,wood sawdust,rice husk,plant straw,etc) Plastic(Recycled PVC powder,orginal PVC powder)

Production proecss:

PVC Wood Plastic Composite : milling→mixing→extruding→final product surface treatment

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber.

2)With scientific and reasonable technology,the machine has high efficiency and runs stably

3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt.

4)This is one step WPC extrusion technology,which saves energy

5)This production line can produce wpc products of different specifications only to change mold.

6)Imported PLC automatic control.

automatic feeding machine and dryer hopper

Siemens motor/ABB inverter/Omron temperature controller

The part which connect with water is made of stainless steel.

Equipped with dust collection device.

Stacker

Put the final product on it after cutting

By adding the extra single screw extruder,the WPC profile can be coated by colorful plastic layer to get the colorful surface.

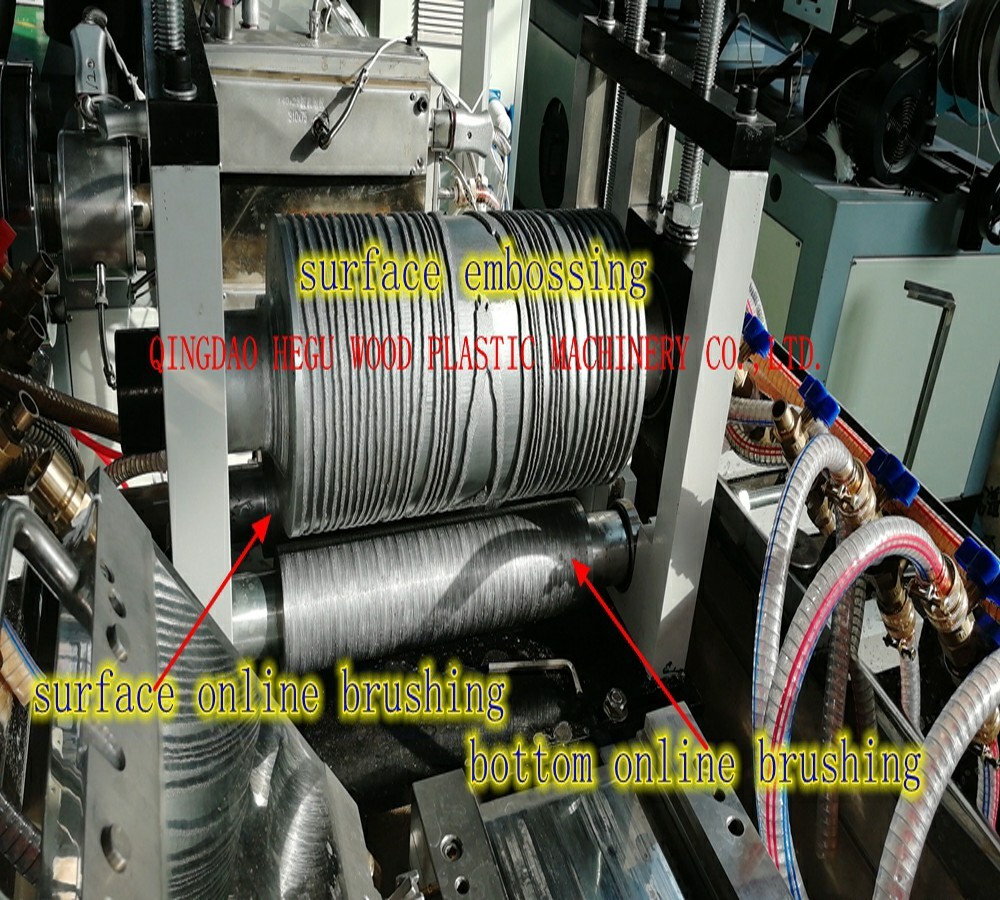

After online embossing roller,the WPC profiles are embossed with wood pattern during the production.It will save the production

time.

Co-extrusion WPC profile/decking making

Reviews

There are no reviews yet.