Description

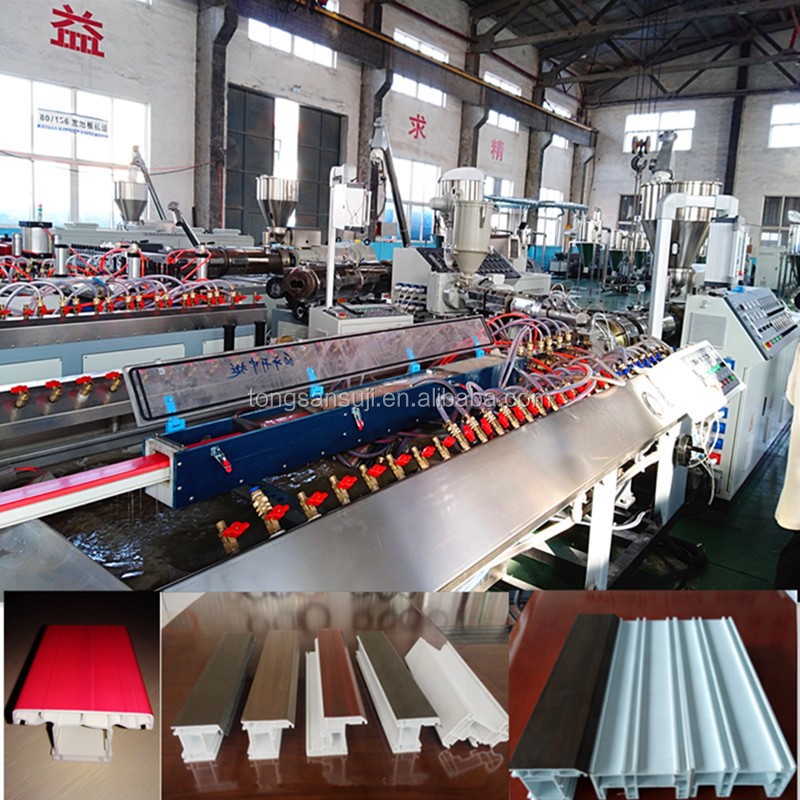

This PVC profile machine is specializing in producing PVC plastic profiles including ceiling panel,windows and doors, decorative plates,foam profile etc.

By absorbing advanced technology from abroad, our company developed the large plastic profile extrusion line, which is equippedwith conical double screw extruder, and it possesses the advantage of high degree automation, stable performance,high output and efficiency, etc

Features:

1.The equipment adapts to various formulations, the ratio of calcium can be increased up to 50%-250%, while the required accessories can be reduced by 30%.

2. The ceiling that the extruder products has an exquisite appearance and uniform plasticization.

3. Laser tracking eliminates problems of the extrusion flow rate, which is helpful to achieve automation of the entire extrusion process.

4 The PVC ceiling extrusion machine has auto-alarm functions in case of emergency, through the use of PID controller.

The component of PVC ceiling panel extrusion making machine

| Item | The description of the machine part | Quantity |

| 1 | Auto Screw Feeder | 1 set |

| 2 | Conical double screw extruder (SJMS65/132,SJMS51/105,SJMS 55/110) | 1 set |

| 3 | Mold system(including die head&molds) | By request |

| 4 | Calibration platform machine | 1 set |

| 5 | Haul off machine | 1 set |

| 6 | Cutting machine | 1 set |

| 7 | Product Stacker | 1 set |

| 8 | Electric control cabinet | 1 set |

Extruder for PVC Ceiling Panel Machine

Conical double screw extruder specially designed for making PVC ceiling panel machine

Model: SJMS65/132 ,55/110 model

Main power: 37KW

Capacity: 150-240 kg/h

Max. product width: 200-600mm

Die head and mold for PVC ceiling panel machine

For making PVC ceiling panel making machine, it is necessary to increase the calibrator length to be 300mm*3 piece or 300*4 piece.

and the water cooling tank should be 4000mmor 6000mm

calibrating machine for PVC ceiling panel making machine

Length of table: 6meter customized

width of table: 1100mm, valiable inner width is 600mm

material of table: stainless steel

cooling method: water cooling and vacuum forming

Equipped with water pump and vacuum pump

haul off machine for PVC ceiling panel making machine

Haul off type: double caterpillar

length of haul off: 2.4 meter

control of haul off: frequency control

motor : 1.5 kw

gearbox: double gearbox

Cutting machine for PVC ceiling panel making machine

cutting method: automatic cutting

cutting control: PLC control

Length: fix length cutting

If you are interested PVC ceiling panel extrusion making machine,please contact me at any time.

Mobile/WeChat/WhatsAPP:+86 15269260792

Email: [email protected]

Reviews

There are no reviews yet.