Description

PE/HDPE/PVC double wall corrugated pipe making production machine adopts extruding and forming process, it has the featuresof reliable quality and high efficiency.Compared with other plastic pipe wall structure ,double wall corrugated pipe has excellent wall structure design,its low weight reach the lower production cost and improve the market competitiveness.The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessiories installed,and quality reliable.

The machine has the function of automatic demoulding when power is off.

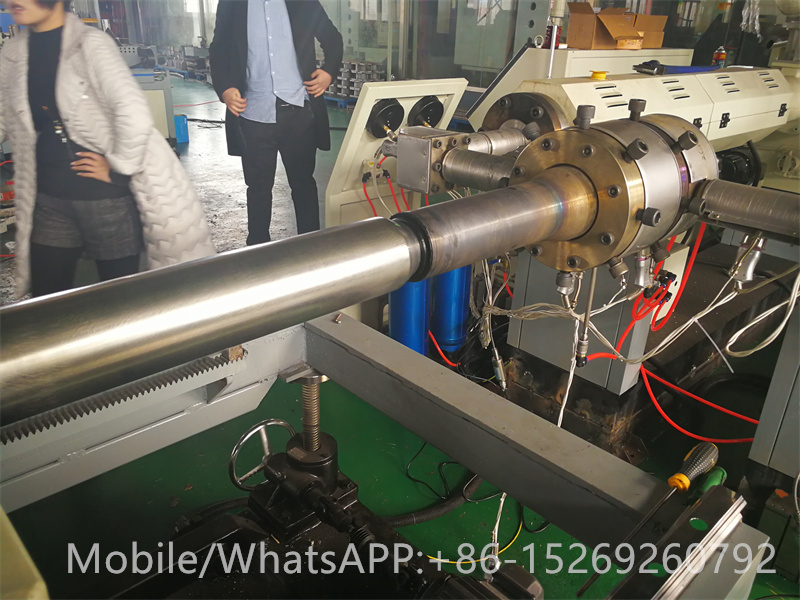

The extruder adopt high-efficiency screw, the die head adopts double-layer spiral structure, mould die and core die being nitrided.

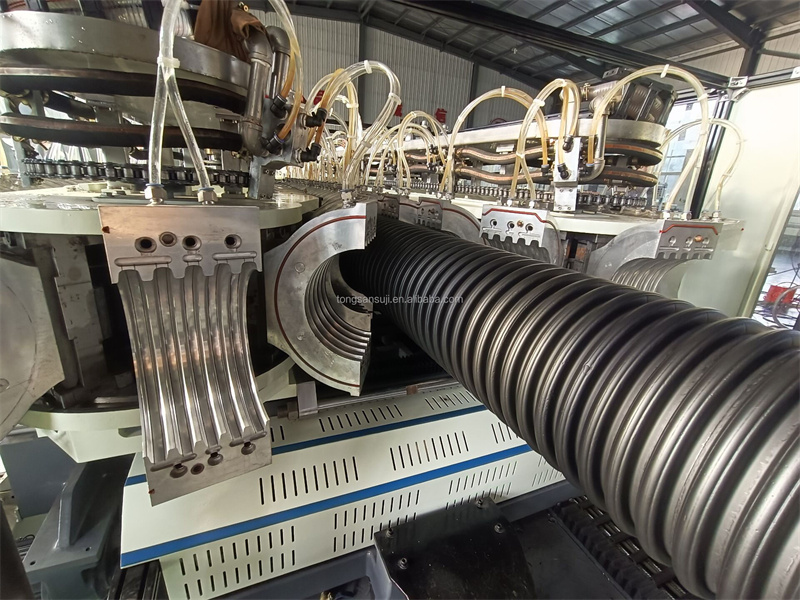

The forming machine adopts vacuum forming type, equipped with automatic lubrication system.Forming mould is made of aluminiumalloy, adopt water cooling type.

The pipe can be cut by on-line cutting machine automatically.

Double wall corrugated pipe is mature product which has the advantage of low weight, low cost, anti-corrosion,good ring stiffness and flexibility.

Our company has developed PE double wall corrugated pipe extrusion line formore than 25 years. We have the whole series of double wall corrugated pipe machine: horizontal type, verticaltype and shuttle type.

Electric control system

Two extruders

Die head&Water Jacket

Forming machine/Corrugator

Molds

Chipless Cutter

Stacker

Winder

Application of HDPE double wall corrugated pipe

2. Municipal engineering, underground drainage and sewage pipelines in residential quarters;

3. Irrigation and drainage of farmland water conservancy; drainage pipes for sewage treatment plants and garbage disposal sites;

4. Chemical ventilation pipes and chemical and mining fluid conveying pipes;

5. The overall processing of pipeline inspection wells; high-speed kilometers of pre-buried pipelines;

6, high-voltage cables, post and telecommunications cable protection sleeves, etc

Reviews

There are no reviews yet.